making cycle counts throughout the yea

r? Aren’t yearly counts kind of tedious and potentially expensive?

Yes, we did. And yes, they are. But that doesn’t mean you shouldn’t do a yearly inventory anyway. Here’s why.

Though it’s very true that cycle counts offer a wealth of advantages for retailers, (particularly when it comes to products that tend to fly off shelves), there are also some compelling arguments for conducting an exhaustive yearly stocktake of each and every one of your physical items. In fact, the case for yearly inventory is so strong that some industry insiders such as the small business advisor The Balance suggest certain retail operations might benefit from a hybrid inventory counting program—that is, a system that combines item-specific cycle counts at regular intervals with one larger, storewide count hosted once or twice a year.

We’ve compiled a list of some of the top reasons to implement a yearly stocktake as part of your inventory management procedure. Of course, the final decision regarding cycle vs. yearly counts is up to you, but we hope you’ll consider our list carefully before settling on definitive plan. (Remember, you can always use both types of procedures.)

Yearly counts — as opposed to cycle counts — enable you to…

1. Comply with industry regulations.

There’s no getting around it: If you’re a small business owner, yearly inventory counts are basically part of your legal due diligence. According to the IRS, small business owners are required to value their collective inventory at the beginning and end of every year, ostensibly by conducting two separate physical counts of every item in stock.And this makes sense. In order for your tax filings to be above board, your written financial statements have to match your holdings in store — and the only real way to assure the numbers on file agree with the number of products on the shelves is to tally up all your items in person. An added bonus? Any losses you report (i.e., due to damage, theft or missing orders) may yield a reduction in tax liability. You may be disappointed at taking an inventory hit, but you’ll probably be grateful for the tax break.

2. Uncover mistakes in your records and facilitate smoother business operations.

No one wants to believe their product data is inaccurate. Yet, while we’re sure you do everything you can to maintain pitch-perfect, up-to-the-minute records, human error is a fact of life. Despite your best efforts, a few digits may be entered incorrectly or a comma misplaced by accident, all of which could spell potential disaster for your business. An annual stocktake may provide a solution.

What yearly counts may lack in excitement, they more than make up for in pinpoint accuracy. And once you have a complete and precise inventory count, you can cross-reference the results against your in-house records and flag any discrepancies, which will provide better business oversight and steer you clear of any number of catastrophes (including incorrect earnings reports, misinformed stock orders, etc).

In addition, as Entrepreneur.com observes,

comparing recorded and physical inventories

can give you “an idea of the loss of goods through theft or disappearance.” Similarly, a detailed account of your inventory obtained through a storewide physical stocktake can offer enhanced insight into which items are moving and when, thereby facilitating more effective inventory management processes that help you anticipate customer needs (more on this below).

3. Avoid employee burnout.

This one may seem counterintuitive (are we actually suggesting that one big stocktake is easier on your staff than several little ones?), but we think it bears consideration.While cycle counts may work well for some small business employees, they can be a bit overwhelming to staff members in certain situations. What if, for example, your retail business has more SKUs than can be tallied by a handful of workers on a cycle schedule in a single year? Or what if items move so fast that cycle counters are forced to make constant revisions to accommodate those products that sell during a count?

Under these circumstances, mistakes are almost bound to arise and employees are likely to feel pressured and frustrated. The answer? One or two large inventory counts taken during a storewide shutdown with all hands on deck. What you may lose in revenue due to overtime payments or lost store hours, you’ll most likely gain back in reliable SKU numbers and boosted company morale.

4. Keep track of broader trends.

It may be great to get a sense of how products are faring from week to week, but what about year to year? Cycle counts may trace consumer habits in real time, but they’re not necessarily the best tools for taking in the bigger picture. Yet, as we touched on earlier, yearly counts allow you to zoom out and view purchase histories from a long-term perspective. Summer items like baseball caps and sunscreen may play well in June and July, but they might prove to be poor performers overall if you track their total sales from January to December. Once you observe how items are faring over longer periods of time, you can adjust your finances, order schedules and pricing accordingly and potentially keep business booming all year long. 5. Revise and rejuvenate your business in time for a new year.

All those New Year’s clichés like “ring out the old, ring in the new”? They hold true for business as much as they do for your plan to hit the gym. Think of a yearly count as a parting gift from the outgoing year and blueprint for how to navigate the upcoming 12 months — a way to revitalize your business with the help of the lessons you’ve learned from the previous fiscal year combined with a crisp, clean summary of your product numbers. Any data errors or overage screw-ups are now a thing of the past. As of this (hypothetical) moment, you can use your end-of-the-year tally as a new baseline moving forward…a restart button for your enterprise. Champagne, anyone? Using a POS for physical stocktaking

It’s no secret that utilizing a POS is a great way to boost profits and streamline workflows. What business owners often look over is the fact that a POS can also be used to assist with stocktaking. Semi-automate your stocktaking

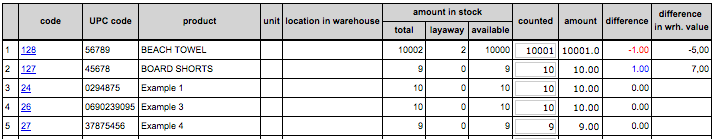

While your POS can’t physically do the heavy lifting for you, it can be a huge help in alleviating the tediousness that comes with conducting a stocktake. A great POS won’t just list your products, it will highlight discrepancies, semi-automate numbers, allow you to register or write-off inventory, and identify logistics for each inventory entry.

Erply, for example, has tools to make stocktakings complete much faster while minimizing human error. Say you know that you purchased only 50 units of sunscreen during the year and that you sold all 50. Even though you know your inventory count, you still want to include them in your stocktaking records for the sake of conducting an accurate count. With the press of a button, you can enter the default inventory amount for every inventory item that you didn’t count in the POS. This feature is a huge timesaver and can prevent manual entry errors from occurring.

Flexible options

One of the great things about a POS is that it can be accessed from virtually anywhere. Work on your store’s computer, grab a mobile tablet, or work straight from your warehouse - your POS enables flexible stocktaking. This allows more employees to contribute to a stocktaking at once, easing the daunting process of conducting a yearly stocktake.

Paper trails

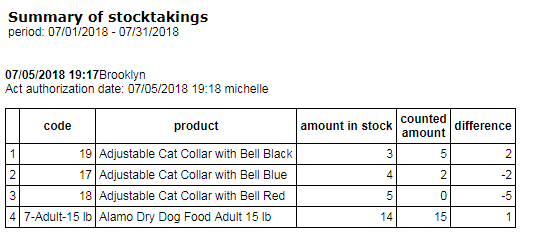

As we mentioned earlier, you’ll want to learn from your stocktakings and adjust your purchasing strategies according to the numbers revealed from your yearly physical stocktake. When you use Erply to conduct a stocktake, you can retrieve those reports at any time and from any device. Pulling reports from each year’s full stocktake can help you quickly identify purchasing trends so you can plan your orders right away.

Again, the ultimate decision regarding what type of stocktake you’d like to employ is entirely yours to make. Still, you shouldn’t turn your back on yearly counts just because they may appear inconvenient at first glance. Cycle counts have immense benefits, but so do their yearly cousins. One or two big tallies throughout the year may be essential to the health and maintenance of your retail business operations.

We recommend giving them a try.