- How can I

transition my inventory management from manual processes

to more efficient automatic ones? - How can I revamp the

layout of my warehouse

to handle increasing inventory levels? - How can I

maximize my team’s efficiency

without having to hire more people? - How can I

integrate inventory management with POS data

? - How can I

track important metrics like fill rates and return rates

? - How can I do all of these things without spending every last dollar I have?

ion.

Do You Have a Warehouse Management System?

When your business is small, you can often get by with manual or improvised warehouse management processes. However, as you grow, the more important it becomes to instill a process that accounts for each step of the inventory management process -- otherwise, you risk confusing or frustrating your employees (and customers) and making costly errors.A POS with warehouse management tools, such as Erply, can help your company run more efficiently while also eliminating the potential for human error. Automating work processes and customizing them to fit the needs of your business can cut costs and make a huge difference in productivity.

Here are the top four things you can do right now to start implementing an effective warehouse management system and better prepare yourself for b

usiness growth.

#1: Establish roles.

Even as you automate key aspects of your warehouse management, you’ll still need to hire the right people to do jobs only humans can do. And while you might be doing most of these tasks yourself, as you grow, you’ll need to enlist additional workers like a warehouse manager or supervisor, pickers, packers, receivers, and possibly delivery truck drivers.

And while you’re looking to employ the best possible people, analyze your supplier options, too. If you’re having any trouble now with late deliveries or problems with order fulfillment, you’ll want to switch to a different supplier before business really starts to boom. Working with a POS that has supplier management features can be beneficial for your employees, especially if your business deals with multiple suppliers and locations. Erply’s back office lets you easily add and organize supplier information by location, type of supplier, or their relation to your employees

#2: Organize your warehouse.

Organize your warehouse first by aisle, then by vertical section, and finally by level number. Spend time walking through your warehouse to consider the height of your racks, the space in each aisle, and how your warehouse operators will be scanning products. You may find that by lowering racks or narrowing aisles you can significantly increase your space available, while also making it easier for your warehouse operator to work quickly.

#3: Improve your labeling.

Your warehouse operators need to be able to scan inventory quickly and accurately as your small business grows. Make sure operators can scan barcodes from a distance and ensure barcodes are printed large and dark enough for operators to read. Place labels consistently and in a position where operators can see them from a distance. Opt for thermal transfer printing for your barcodes, which makes labels more resistant to degradation over time. Consider upgrading your scanning hardware as well to increase accuracy and speed.

Quality is a huge factor when printing labels and Erply’s software can help you create accessible, high-quality labels. Erply’s label platform creates labels in a PDF vector format to ensure a consistent layout no matter the platform used to print. Erply uses Layout Logic Algorithms to preemptively correct errors in data formatting so your employees won't have to spend time manually correcting labels

#4: Use inventory management software that aggregates data from multiple sources.

Imagine two customers simultaneously place a large order of Item A online, while a third customer does the same thing in-store, and a fourth makes a purchase through a sales rep. If you’re using different POS and inventory management software for all of these channels, you may struggle to fulfill all of your customers’ orders on Item A. But with an all-in-one software, you’ll always have a high-level view of what’s happening across store locations, both online and offline.

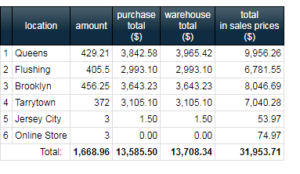

Because managing large inventory quantities throughout multiple locations can quickly become a complicated process, Erply puts a huge focus on inventory management. Detailed reporting, tracking across multiple locations, and two-step transfers are all offered by Erply, and that’s just scratching the surface of our inventory management tools. Finding a POS that can be customized to the way your business works will save you and your employees the headache of dealing with complex orders or low inventory levels.

#5: Measure and track everything.

The amount of data available to you as a small business owner is worlds beyond what it used to be. With the right software, you can analyze key performance metrics that can seriously impact the way you do business. In regards to inventory, you can track things like order fill rate, inventory turn, order cancellation rate, and cost per back-ordered unit. With this data, you can hone in on which steps in your warehouse management process need improvement.

In addition to tracking inventory data, take a hard look at POS data as well. Reflecting on the performance of evergreen products during different days and seasons can help you anticipate when you’ll need more or less inventory in your warehouse. Erply lets you print detailed inventory reports for any of your warehouses or store locations so you can easily identify different inventory trends.